ViOptix Intra.Ox Disposable O-Ring Design

Problem statement

In 2018, when I first joined Triple Ring for an internship my junior year of college, the company was in the midst of establishing a strong relationship with a company called ViOptix, which was actually housed inside our building. ViOptix specializes in medical equipment that can measure oxygenation levels in tissue (StO2), which is very similar to a pulse oximeter (what a patient wears on their finger at the hospital that tells the nurse whether your blood is oxygen rich or oxygen-poor) but is used specifically on tissue post-surgery to determine whether or not tissue needs to be removed prior to suturing up a wound.

At the time, Triple Ring was working on a handheld version of their existing benchtop technology, which was called the T.Ox (for “tissue oximeter”, see “T.Ox device” image for details). We named the handheld version the “Intra.Ox”, which was split into three key assemblies.

My role

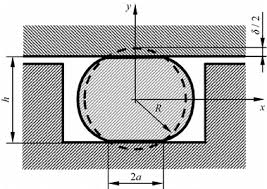

One of the key design features of the sheath is the custom O-Ring. One of the first things I learned at Triple Ring was why O-rings are able to function the way they do, even at high fluid pressures. The beauty of an O-ring is that it is designed to be squished and deformed from a circular cross section to an oval. This intentional compression absorbs local surface imperfections and discontinuities on the two “rigid” bodies that are compressing it as shown in the “O-Ring compression” diagram below. As a result, fluids (both gas and liquid) have a hard time breaking the O-Ring barrier because there is no physical “escape route.” Typically, with two rigid bodies (for example, two pieces of plastic) compressed together without a soft rubber O-Ring in between, the local surface imperfections offer a path of escape for fluid, or a “leak.” It doesn’t matter how small the path of escape is or if it’s visible to the naked eye, if there is a pressure differential, fluid will find its way out and leak.

T.Ox device details

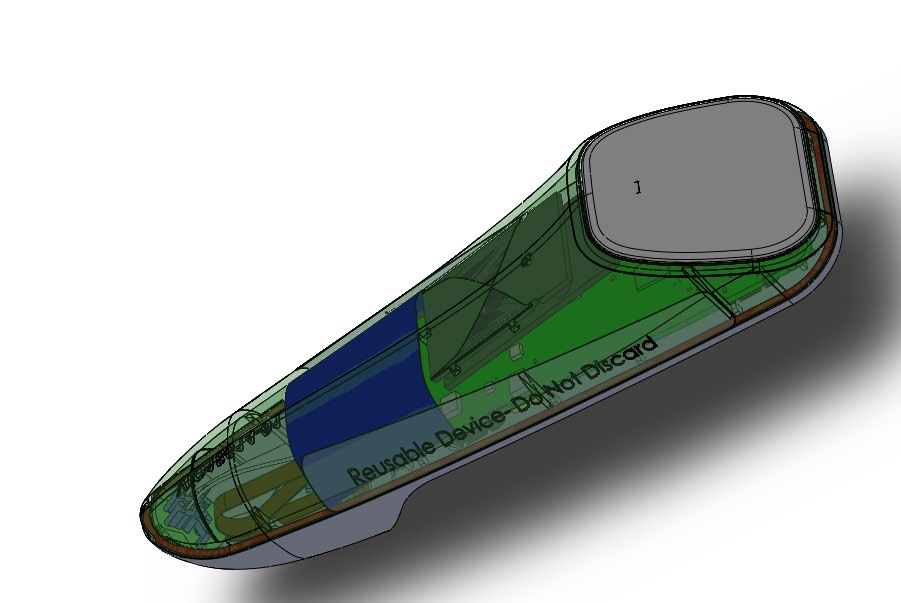

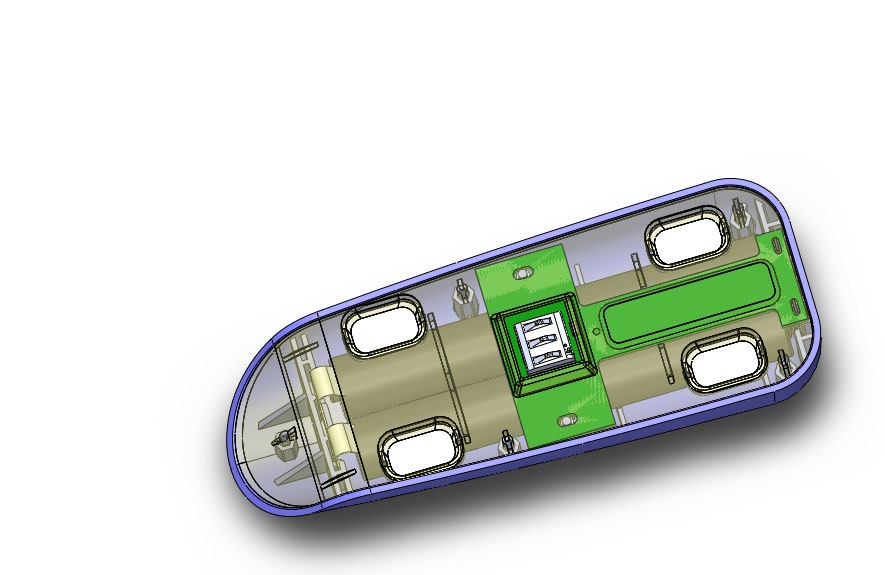

A “durable” which drives the core electronics and optics of the device, collects readings through optical properties and reports them back to the device user on the screen. We called this device the “durable” because it could be used up to 100 times, making it more economically viable (see below for CAD representation of the durable in our SolidWorks system).

Intra.Ox Durable CAD model (left)

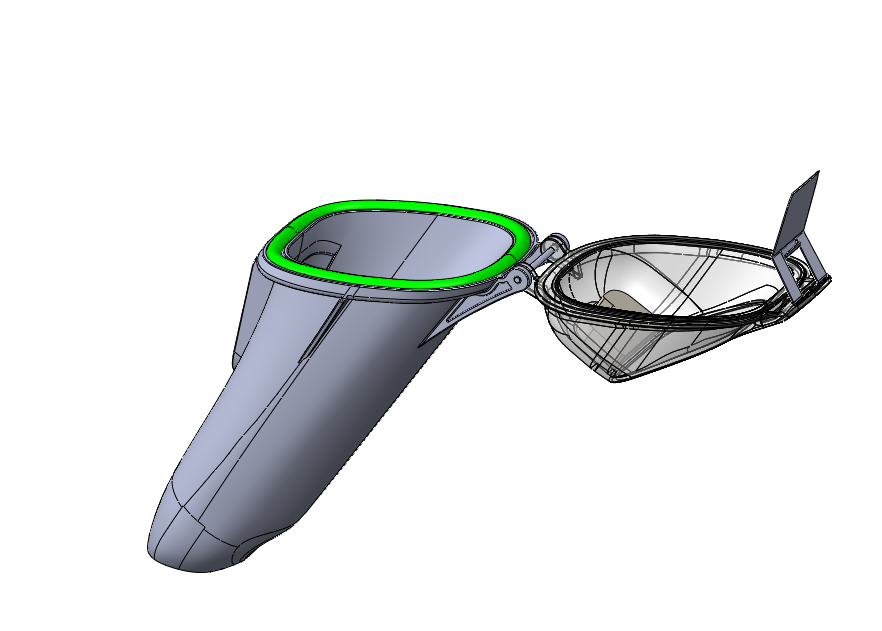

The device also consists of two “disposables.”: A custom battery pack, which holds four AA batteries and can only be used for one surgery that is attached to the durable each time and then discarded post-surgery, and a disposable, called the “sheath,” which is a casing/enclosure that goes around the durable and battery pack (see below). The purpose of this sheath is to keep the durable protected from any germs or bacteria it might otherwise interface with without the sheath. In other words, the sheath was designed to absorb the brunt of the bacteria, blood, and germs that are typically found in the ER so that the durable could be safely removed at the end of the procedure and be re-used the next day (with a new sheath and battery pack) without having to worry about it being contaminated.

Intra.Ox Disposable Sheath (left) and battery pack (right)

O-Ring compression diagram

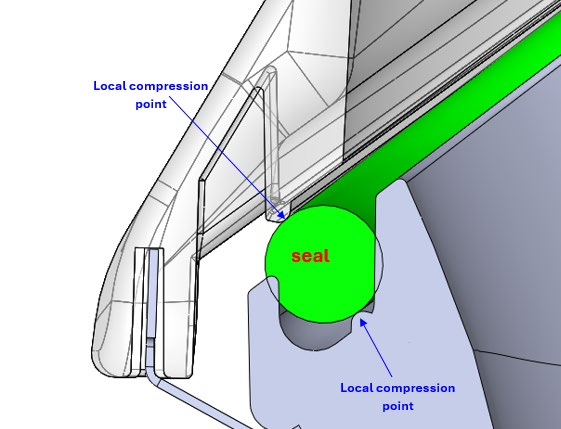

Unlike typical O-Ring design, which ranges on a hardness scale from 30 to 100 shore A, we knew our design was going to be slightly softer (somewhere between 10 and 30 shore A) for a number of reasons. First, we calculated that the pressure differential between inside and outside the disposable sheath could be 1 PSI maximum, driven by temperature fluctuations in the room and the overall temperature change of the durable device during “warm up” (when the device is turned on). Because we didn’t have to hold a high pressure differential, we knew we could afford to go softer and still hold a seal. Unfortunately, on the flip side, because one of the human factor requirements was that a weak nurse needed to be able to close the sheath lid with less than 4 lbs. of hand force, we had to design an O-ring that was compliant enough so that our latch mechanism would close with less than 4 lbs. of hand force. As a result, we decided to leverage a seal design that we modeled off of a Pelican™ Case, as shown below. The idea was to create a local compression point on both sides of the O-Ring, which would allow the seal to hold without the lid needing to be closed with too much hand force.

O-Ring cross-section, localized compression

Although the overall shape of the O-Ring was not circular, we used ma set of circular “fixtures” to oversimplify what we were trying to solve for.

We had to determine the stiffness of the O-ring so that it’s not too stiff and makes the lid too difficult to close especially under maximum material condition. At that same time, the O-ring could not be so compliant that it could not seal under least material condition.

Also built into the least and maximum material conditions and the tolerance stack up was

choosing our custom O-ring’s cross-sectional diameter, as well as the O-ring seal design itself. Ultimately, my testing and data revealed that if we were to choose a 5 mm O-ring diameter (which the tolerance stack math was suggesting would give us between 10% and 30% local compression on the extremes of the tolerance stack up), 15 shore A was the right stiffness for the O-ring. Unfortunately, making material below 30 shore A can be “volatile” in the sense that it is harder to control the stiffness.

Through working with large O-ring companies like Apple Rubber, we discovered that most O-rings above 30 shore A are manufactured and held to ± 1 shore A (that is, if you buy 10,000 off-the-shelf O-rings at 35 shore A from Apple Rubber, all 10,000 are guaranteed to between 34 and 36 shore A). Once you drop down into the 10–20 shore A range, the tolerance typically drops to ± 5 shore A. We ended up working with a vendor called RD Rubber in Los Angeles that would design our custom O-ring mold and would shoot production level parts for us (roughly 1000 a year). Towards the end of my internship when we were getting ready to order our final design for a batch of design verification sheath disposables, we developed a process with RD Rubber such that they could determine right after a batch of 2 -part liquid silicone rubber is mixed what the stiffness was going to be before the material cured inside the mold (using shore A hardness measuring equipment). We leveraged this equipment so that, through empirical testing, each lot of O-rings was molded somewhere between 13 and 17 shore A, which was enough to meet the design requirement for the Intra.Ox.

Project outcome

When I returned to Triple Ring a year later for a full-time job, the final sheath disposable design (including my O-ring) had passed FDA clearance, and was being manufactured at two assembly houses—or contract manufacturers (CMs)—that ViOptix had worked with in the past. While I was away at school that year, my Triple Ring colleagues helped pass on the build instructions, vendor and BOM information, and key test equipment and fixtures required for assembly to these CMs. By the time I had returned to Triple Ring, both CMs had become fully self-sufficient, no longer relying on Triple Ring for parts, fixturing, software, and verification equipment. To this day, ViOptix makes about 100 durables a year, which go to various hospitals around the country for free. ViOptix also makes around 2000 disposable sheaths and battery packs each year. They sell these to each hospital, knowing that if a given hospital is doing 300 surgeries a year, they will need to purchase at least 300 battery packs and 300 sheaths.

© 2024 ariksingh.com. All rights reserved