Independent study at UCSD

Description

Independent study at UCSD, 2 quarters. Write a paper with Professor James friend called “An investigation of maximum particle velocity as a universal invariant—Defined by a statistical measure of failure or plastic energy loss for acoustofluidics applications”

Problem statement

I first joined Professor Friend’s lab in 2017, right after I took his class on advanced analytical methods for solving non-linear ODEs using MATLAB. I was the only undergraduate in his lab, so there was a limited number of projects he could assign me due to my limited expertise.

Over the years, Professor Friend noticed a trend across his experiments, which typically dealt with vibrations through robotics that happened at high frequencies. What he discovered was that if you solve for the maximum particle velocity inside a vibration wave in a solid (typically longitudinal but also can be transverse or shear waves), it never exceeds 1 meter per second regardless of the frequency of vibration. We believed this to be a fundamental property in nature, regardless of the material properties of the solid that is vibrating.

My role

Solving for vmax as a function of yield stress (σy), elastic modulus, (E) and density (ρ) (equation shown to the right)

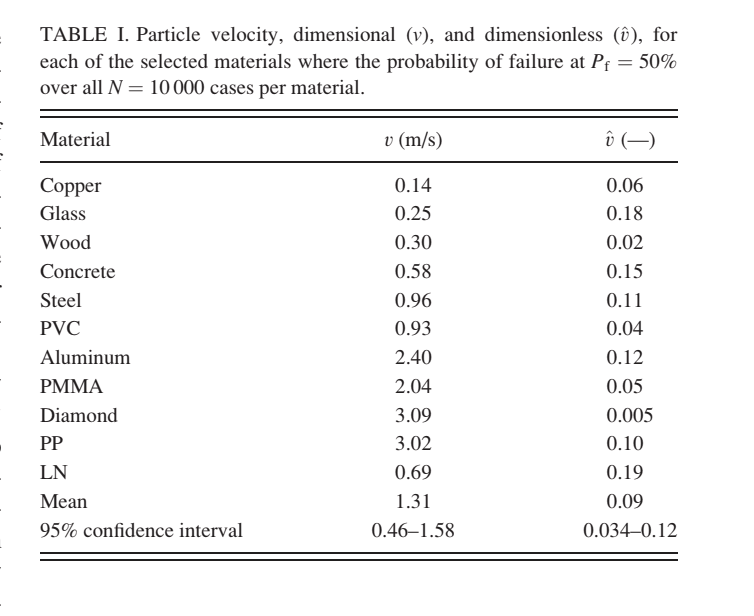

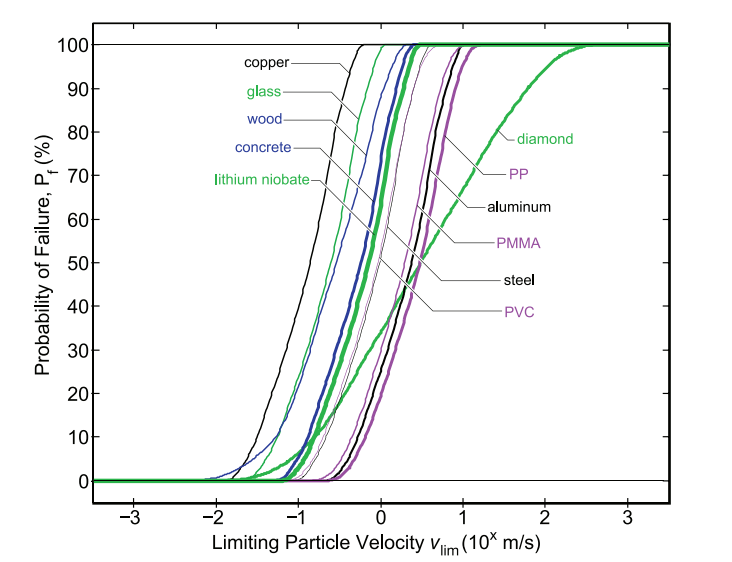

To determine the range of vmax values in nature (in meters per second), we settled on 11 materials that range all over the spectrum of solids (metals, plastics, rubbers, etc. —wood, diamond, copper, PVC, PMMA, steel, aluminum, polypropylene, concrete, glass, lithium niobate (a synthetic salt))— and calculated their vmax values. Unsurprisingly, most vmax values ranged from 0.1 to 10 meters per second, with diamond being at 100 meters per second due to its unique material properties (high yield stress relative to density and elastic modulus). However, we concluded that because vmax is an ideal interpretation of the velocity limit, real life material samples often have imperfections that can cause stress concentrations and induce crack propagation or material failure well before the particle velocity reaches vmax.

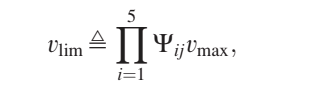

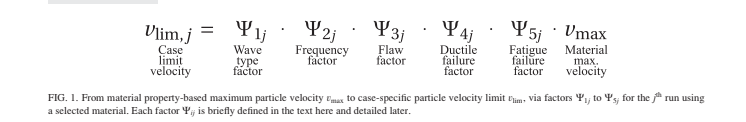

Solving for vlim as a function of vmax and Ψ1 – Ψ5 (left)

Project outcome

About two years after I graduated, Professor Friend called me to congratulate me on the work I did years earlier to get this paper published. Professor Friend and Naiqing were able to leverage their acoustofluidics contacts at the the Journal of the Acoustical Society of America (JASA) to get the paper published, and the project was a resounding success.

© 2024 ariksingh.com. All rights reserved