Bill of materials (BOM) and inventory tracking process development, Triple Ring Technologies

Problem statement

At Triple Ring Technologies, we use a software called SolidWorks to design parts, put together assemblies, and make drawings. For mechanical engineers operating in any design space, SolidWorks is the gold standard. An underutilized tool of the program is the ability to take a large assembly file (typically split into smaller sub-assembly files with many custom and off-the-shelf parts comprising the building blocks of a product) and output a bill of materials (BOM). For years, even before I joined Triple Ring, much of our BOM process was manual. Engineers would have to update Excel BOM tables every time they would add a screw or change a part number. Additionally, much of Triple Ring’s old inventory tracking process (which involves making sure engineers have ordered enough of each part number to build X units) involved manually updating Excel spreadsheets as well.

Our goal was to create a process where BOM tables and inventory tracking spreadsheets would automatically update based on live changes to the SolidWorks CAD (e.g., a new part number is added to the BOM).

My role

In the summer of 2022, I was given the task of working with our intern to improve the BOM process.

My first order of business was integrating our PDM software, Windchill, with SolidWorks to create a series of variables that would be crucial for creating BOMs. These variables include vendor name, vendor part number, and cost; these can be filled in on any given part or assembly file (including OTS screws, custom parts, and custom assemblies). This information becomes SolidWorks metadata, which can be outputted in a BOM-friendly format to Excel.

I discovered that we could develop a SolidWorks script that could effectively parse large SolidWorks assembly information into an indented and flat BOM text file. Unfortunately, in doing so, engineers would have to rely on the default SolidWorks Excel settings, which are not user-friendly. I also discovered that we can use a text file to convert from SolidWorks to Excel, acting as a medium of sorts. This medium gave me the flexibility to leverage Excel settings in addition to SolidWorks’. In turn, we created an inventory tracker and indented BOM Excel templates that provide the necessary information to the reader in a simple and effective format.

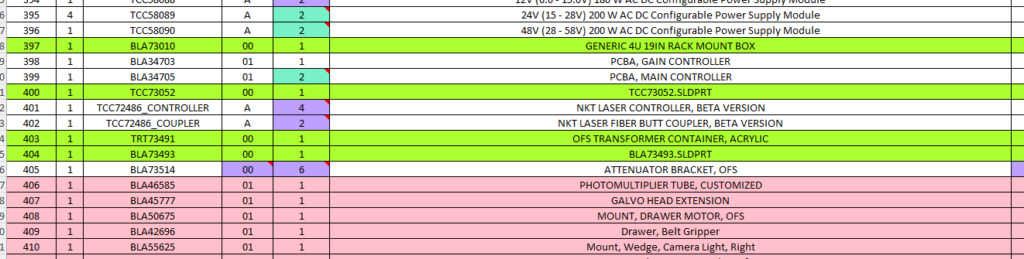

Once a script was established for producing the indented and flat text files, an Excel template was created for project-specific indented BOMs. This Excel template takes in the indented text files and outputs a BOM that is easy to read and well-formatted, and it can give clients the overall cost and goods of making a unit, including labor (often called cost of goods and services, or COGS as shown below). This template was straightforward to implement because it relies solely on the current indented BOM text file and nothing else.

BOM Template example (right)

Conversely, the inventory tracking template took a little longer to create and test. The difficulty of the inventory tracker is the history of the BOM and what already exists in inventory is relevant in addition to the latest flat BOM text file.

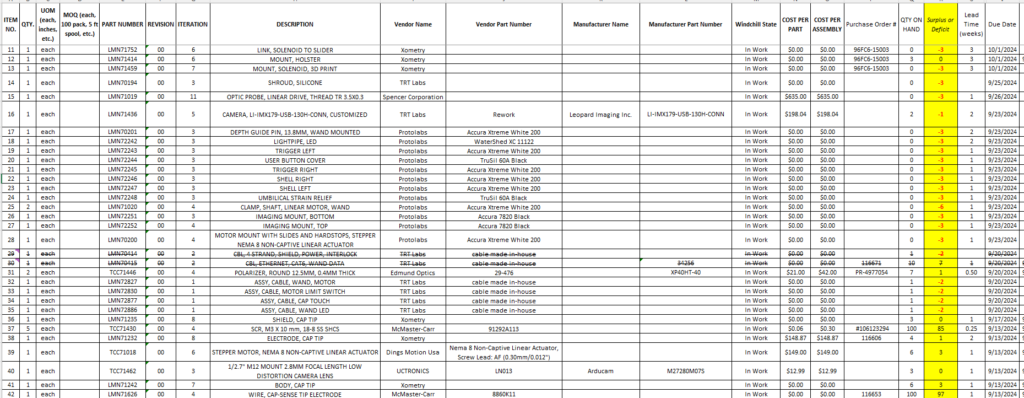

In this template, the idea is to compare the existing list of parts needed with the new list of parts needed that SolidWorks is reporting based on the most recent updates by the engineering team. The first script in this template will tell the user if there are any new part numbers, any part numbers that are old and have been removed from the CAD, or if the quantity of any part number has changed. These results are reflected in the SolidWorks export tab as shown below.

SolidWorks export tab (green = new, red = old, turquoise and purple represent a mismatch between the new SolidWorks export and the master inventory tracking tab)

A second script will reconcile these differences on the master tracking tab. After a complete sequence (first and second script both performed), the tracker will inform the engineering team, via a variable called surplus/deficit, whether or not there are any part numbers on the tracker in which Triple Ring needs to order more in order to complete the requested number of builds (e.g., do we have enough parts to build 3 units, as shown below).

Master tracking tab, surplus or deficit column highlighted yellow (right)

Unlike the BOM template, which has an element of well-thought-out formatting and can be shared with the client and sometimes the FDA, the inventory tracker template is exclusively for the internal Triple Ring engineering team. The goal is to use this document as a live tracking tool to make sure that every single part number is accounted for and purchased in order to complete a build.

Project outcome

The project was a resounding success. At first, we sampled the BOM and inventory tracking templates on a pair of devices with a relatively small build of materials. On both projects, the BOMs were no more than 40 lines long. While a case could be made that these tools were not saving time for smaller BOMs such as these, we were using both projects as a proof of concept that these methods would work with our workflow and existing processes.

Due to the success of our proof-of-concept BOMs and trackers, we decided to open up the tools companywide to all projects, including a recent project we have been working on with a BOM of over 1200 line items. Just like on the smaller scale, the BOM template and the inventory tracking tools are able to work with larger BOMs and can instantly get the end user what they need.

Now, nearly three-quarters of the active Triple Ring projects are using both the intended BOM and the inventory tracker spreadsheets I created as necessary project tools for both completing projects in a timely manner and designing products with full traceability.

© 2024 ariksingh.com. All rights reserved