Auris Health

Problem statement

In early 2019, when Auris Health was still a startup company in Redwood City, they hired Triple Ring Technologies to help with the design and manufacturing of the viewer console of their clinical device, which was going to compete with the Da Vinci robot (shown below).

My role

This was the first project assigned to me at Triple Ring as a full-time employee. When I joined the project, we had used a contractor named Rob Campbell to design the most complicated optomechanical parts, ranging from optical housings with complicated machining operations and optical black anodizing finishing requirements. However, it was all designed as a CAD (SolidWorks) assembly; no parts had been ordered yet.

The first steps were creating a manual bill of materials (BOM) of what Rob Campbell had designed into SolidWorks and a list of custom lens manufacturers and machine shops we’d be working with to deliver units (which ultimately ended up being 9 units in three iterations) to our client .

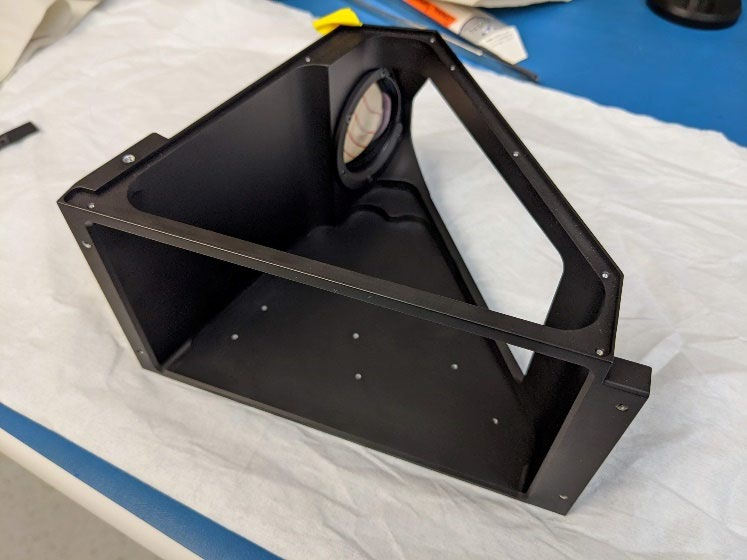

We discovered early that Auris left and right optical housings, which drive almost all of the other parts we were ordering, were also going to be the trickiest to manage due to their complex machining operations (see below).

Da Vinci Robotic Surgical System (right)

The Da Vinci Robotic Surgical System is an industry standard medical device made by Intuitive Surgical (also located in the Bay Area) which can perform a remote surgery. In other words, a doctor can stand on one side of the room with the robot on the other side (with a camera driving what they are seeing inside the patient). They then actuate various de facto surgical tools in front of them (for example, fake snippers and needles). Their hand motions trigger the robot performing the surgery on behalf of the doctors hand motions (via mirroring their actions), which has proven to be safer and cause fewer human-related errors.

Auris assigned Triple Ring the viewer console portion of the device because it requires complicated opto-mechanical part design and tricky manufacturing steps that need to be developed. The idea behind the console is it takes a snake camera with two lenses that goes into the patient and projects an image back to the doctor. Through a series of mirrors and lenses, the doctor can see a 3D view of what is going on inside the patient, which helps with depth perception when they are using their surgical tools. Also, Auris was interested in gaining a competitive advantage over Intuitive Surgical and requested we do our homework in order to design a console that was lighter, smaller, and sleeker than the Da Vinci’s console.

Auris left and right housing, with their lens stacks installed

We met in person with multiple machine shops to discuss the order of operations for machining these parts and for fit checking the lens stack manually before sending the parts for anodizing. These parts typically had an 8-week lead time once they were ordered. During the 8 weeks these parts were on order, we would use that time to develop what we call manufacturing process instructions (or an MPI), which explain how to put the unit together once you have ordered everything listed on the BOM to build one unit.

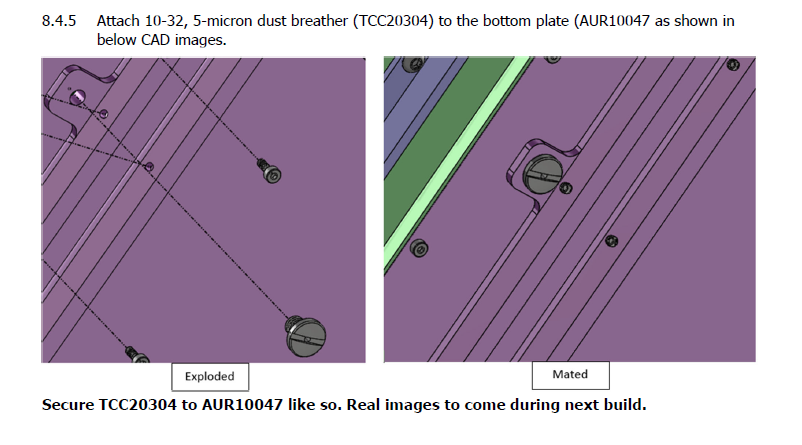

The first time we write an MPI at Triple Ring, we usually have to use the SolidWorks CAD and rely on exploded views to explain how to put the unit together, as shown below.

Write MPI steps using CAD (right)

This is why building the first unit (of any assembly at Triple Ring, but particularly earlystage prototypes) is so important. It gives the engineer the opportunity to replace CAD screenshots with real-life photos while also discovering assembly steps that need future improvements. On this project, my supervisor, Todd Harris used his professional Nikon camera. Todd Harris has an optical background, which was why he was the overall Triple Ring technical lead for the project and he co-wrote the MPI with me.

We built one of each of the first two iterations of the console, Alpha and Beta. Eventually, we were contracted to build seven more design verification testing units, or DVT units, of which four were going to be sent off to a company in the UK called Surrey NanoSystems. Surrey NanoSystems specialized in an optical black coating called Vanta Black (see below), which absorbs 99.965% of light, an optical performance that was better than purely optical black anodized machined aluminum.

Because we had built and iterated on the unit twice, by the time we were ready to order parts for DVT, we had already iterated on the overall design (parts, assembly, assembly sequence) twice to accommodate for design for manufacturing, design for assembly, cable management, electromagnetic interference (EMI) mitigation, thermal management, industrial design factors and human factors. With respect to the 3D-printed parts that housed the machined aluminum, for example, there were industrial design requirements about how aesthetically pleasing it had to look (color and finish) while also accommodating the range of human head sizes, which feature different nose sizes and center-of-eye to center-of-eye distances.

Vantablack

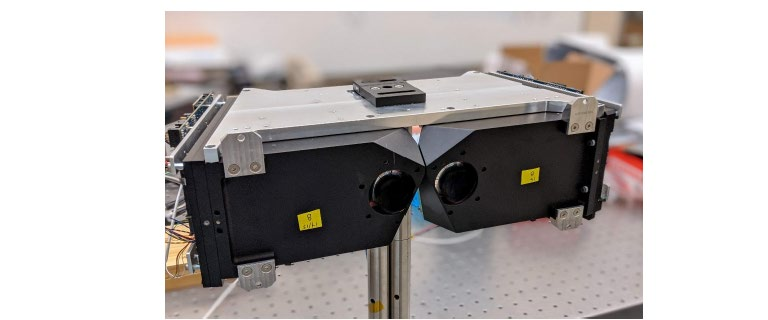

Final DVT Auris Viewer Console mounted to workbench

Project outcome

When we created the contract for Auris for 7 DVT units, we wrote what was called a Statement of Work, which is what Triple Ring uses to define the scope, budget, and timeline of a given project. Unfortunately, around the time we were ready to order parts for these 7 units, COVID hit and Auris Health was acquired by Johnson & Johnson (J&J). Triple Ring did a good job managing the project throughout the early days of the pandemic. For example, Todd Harris and I only came into the office (masks on) on days where we knew we needed to complete portions of the DVT build. Most of our other tasks (which revolved around the SolidWorks design and the respective documentation) could be performed remotely. Unfortunately, the transition from working with Auris directly to working with Auris under the J&J umbrella was not smooth.

Not only did we need to interface with personnel from J&J that drove our weekly technical meeting with the client, but our J&J contacts had very little understanding of the technical challenges of this portion of the device or the Triple Ring and Auris design and device history records which drove much of the design intent and systems engineering up to that point in the project.

Unfortunately, while Triple Ring succeeded in delivering 7 DVT devices that were in specification of the required optical performance of the device (see “Final DVT” figure above for what the final unit looked like), Johnson & Johnson struggled to drive the project beyond that point, unable to integrate our console into a larger assembly context or to scale up and compete with the Da Vinci, which is already fully scaled up in production and has been the industry standard for 20+ years.

In fact, it was recently revealed publicly in court through a $1 billion dollar settlement with Auris that J&J blamed the missed milestone goals on technical problems with the Auris console while also arguing that they had the authority to use Auris’ products in any way that advanced J&J’s overall robotics program (something that became apparent to Triple Ring early on, which is why we chose not to pursue the next phase of this project despite the plan to build 9 more units).

© 2024 ariksingh.com. All rights reserved